Understanding ISO 45001: Key Clauses, Requirements, and Certification Process

Workplace safety isn’t just an obligation; it’s a priority. It is a fundamental human right of every worker and a core component of a business.

Every year, millions of workers get injured, become sick, or even suffer fatalities on the job. This highlights the need for companies to establish globally recognized standards to manage Occupational Health and Safety (OH&S).

It is a worldwide standard for managing workplace health and safety. It helps businesses create safer workplaces by reducing risks and improving working conditions.

This guide will show you what ISO 45001 is. It will cover its rules, main sections, the step-by-step process for getting certified, and how it can benefit your business.

What is ISO 45001?

ISO 45001 is the international standard that sets the framework for Occupational Health and Safety (OH&S) management systems. Its main goal is to help organizations improve their OH&S performance in preventing workplace injuries and illnesses.

- Who developed it and when: The International Organization for Standardization (ISO) created it and officially published it in March 2018.

- Why it matters: Because ISO 45001 helps provide companies with a structured approach to identify and manage safety risks, reduce workplace incidents, and foster a culture of health and safety.

- How it evolved: ISO 45001 replaced OHSAS 18001. Although widely used at the time, it was not yet established globally. ISO 45001 is a better version, with a stronger emphasis on the organization’s leadership and worker participation in the OH&S management system.

You can also explore the difference between OHSAS 18001 and ISO 45001 to better understand how the new standard improves workplace safety and aligns with modern risk management practices.

Understanding the ISO 45001 Standard

Promote a safe and compliant workplace by understanding how the ISO 45001 standard works.

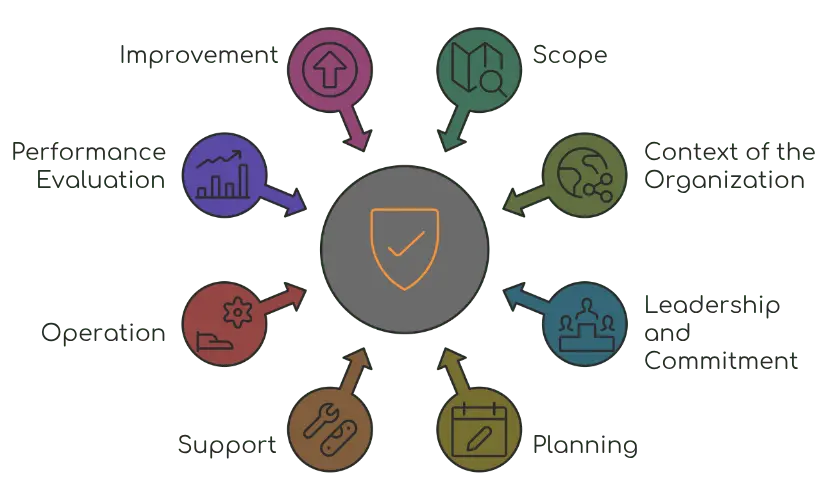

The High-Level Structure (HLS)

ISO 45001 is structured using the High-Level Structure (HLS), a common framework shared by other major ISO standards such as ISO 9001 and ISO 14001. The unified structure enables companies to integrate multiple management systems (MIS), resulting in a more efficient and consistent approach to business.

The PDCA Cycle

At the heart of ISO 45001 is the Plan-Do-Check-Act (PDCA) cycle. This continuous model is designed to enhance safety and performance. And as time passes, it also evolves.

- Plan: Set clear OH&S objectives, define processes, and allocate resources that are necessary to deliver results for your organization’s OH&S policy. (Clauses 4, 5, 6)

The following section will break down these clauses in detail to help you understand how they apply in practice.

- Do: Implement the planned objectives. (Clauses 7, 8)

- Check: Ensure that you monitor and measure processes against OH&S policy, objectives, and legal requirements, and report the results. (Clause 9)

- Act: Take actions to improve OH&S performance and achieve the intended goal. (Clause 10)

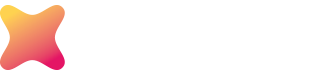

ISO 45001 Clauses Explained

The standard is divided into 10 main clauses:

Clause 1: Scope

- It defines what the standard covers and where it applies. It clarifies that ISO 45001 is applicable to any organization seeking to enhance its safety.

Clause 2: Normative References

- There are no normative references; in other words, ISO 45001 stands on its own without relying on other standards.

Clause 3: Terms and Definitions

- This provides a clear definition of terms such as worker, risk, hazard, and OH&S management system.

Clause 4: Context of the Organization

- Focuses on understanding the organization’s internal issues that may affect the OH&S performance. Additionally, it involves identifying the needs of stakeholders and defining the boundaries of the OH&S management system.

Clause 5: Leadership and Worker Participation

- It’s the most crucial clause. All top management must show commitment and be held accountable. Establish the OH&S policy and ensure consultation and participation of workers at all levels.

Clause 6: Planning

- It covers how companies identify hazards, assess risks and opportunities (both for OH&S and the management system itself). Additionally, it involves establishing OH&S objectives and plans to achieve them, as well as determining legal and other relevant requirements.

Clause 7: Support

- Ensure all the company’s necessary resources, competence, awareness, communication, and control of documented information are in place.

Clause 8: Operation

- This outlines how to plan, implement, and control processes to effectively manage OH&S risks. It includes eliminating hazards, reducing risks, managing change, procurement, and emergency preparedness and response.

Clause 9: Performance Evaluation

- This focuses on monitoring, measuring, analysing, and evaluating OH&S performance, including internal audits and management reviews of the entire system.

Clause 10: Improvement

This encourages organizations to address nonconformities and take corrective actions. To ensure that the system is continually reviewed and improved.

ISO 45001 Requirements

In order to achieve certification, an organization must show that it meets several mandatory requirements, including:

- Identifying hazards and assessing risks for all work activities and processes.

- Establishing OH&S policies and objectives consistent with the organization’s direction.

- Defining roles, responsibilities, and authority within the management system.

- Providing training to ensure workers can perform their duties safely.

- Maintaining documented information necessary to ensure and demonstrate compliance.

- Emergency preparedness and response plans for potential occupational health and safety (OH&S) emergencies.

Continuous improvement of the OH&S management system performance.

Mandatory Documents for Certification (Minimum)

While the standard ISO 45001 allows a more flexible approach to documentation, the following are generally required:

- Scope of the OH&S Management System (Clause 4.3)

- OH&S Policy (Clause 5.2)

- Roles, Responsibilities, and Authorities (Clause 5.3)

- Process(es) for identifying hazards, assessing risks, and determining controls (Clause 6.1.2.2)

- OH&S Objectives and Plans to Achieve Them (Clause 6.2.2)

- Emergency Preparedness and Response Process (Clause 8.2)

ISO 45001 Checklist

When your organization plans to implement ISO 45001, here is the practical, step-by-step checklist they can use to prepare for the certification:

- Conduct a Gap Analysis

Review your current OH&S practices against all requirements of ISO 45001 and identify the areas that need improvement.

- Define Scope and Policy

Clearly outline the boundaries of your OH&S management system and develop a comprehensive OH&S policy that’s endorsed by top management.

- Identify Risks, Hazards, and Legal Requirements

Assess all workplace hazards and associated risks, and determine the legal and other requirements your organization must comply with.

- Establish Documentation and Communication Systems

Create the necessary documented information from procedures, records, and forms. Establish and maintain effective internal and external communication channels regarding OH&S.

- Implement Operational Controls

Put safety controls into action. This includes developing safe work procedures, emergency response protocols, and management of change processes.

- Provide Training and Competence

Train all personnel so they understand their roles and responsibilities in maintaining workplace safety.

- Conduct Internal Audits

Conduct internal audit to verify that the management system is being implemented correctly and effectively.

- Perform Management Review

Have top management review the system’s performance to confirm it’s still suitable, effective, and aligned with your organization’s goals.

- Prepare for External Certification Audit

Address all findings from internal audits and management reviews. Once you are ready, select an accredited certification body to conduct your external audit.

Benefits of ISO 45001 Certification

Earning an ISO 45001 certification delivers value beyond regulatory compliance, like:

- Improved employee safety and well-being through reduced work injuries, resulting in a healthier and safer workforce.

- Fewer incidents mean lower costs and downtime. Proactive risk management means fewer accidents, which cuts costs and can reduce insurance rates.

- Having a strong Legal and Regulatory Compliance, which sets the standard. Ensuring an effective process for identifying and meeting statutory and regulatory requirements.

- Having a stronger reputation and stakeholder trust. The certification itself demonstrates a commitment to social responsibility that enhances your public image and attracts talent.

- Easier integration with other management systems. Its HLS structure makes it easy to connect with ISO 9001 and ISO 14001, which streamlines management.

Continuous improvement culture. The PDCA method builds a habit of always reviewing and improving safety.

How to Get ISO 45001 Certificate?

Certification is a systematic process:

First, conduct a “Gap Analysis” to evaluate your OH&S practices against ISO 45001 requirements and easily identify shortcomings.

Next, you develop and implement the OH&S Management System. Document all procedures, policies, and controls to address the identified gaps.

Train employees to ensure all workers understand their roles, the OH&S policy, and how the new system impacts their work.

Most importantly, audit your system internally to verify that it performs as intended.

Additionally, reviews should involve top management assessing audit results, evaluating system performance, and taking corrective actions as needed.

Select a certification body to audit your system.

- Stage 1 Document Review: This is where your auditor reviews your documentation.

- Stage 2 Audit: This is where the auditor actually evaluates the implementation and effectiveness of the system on-site.

And finally, after all of it, you may now receive certification, and then there’s a cycle of surveillance audits to maintain compliance.

ISO 45001 Training

Conducting effective training is a non-negotiable for a successful system. Using training matrix software ensures that everyone is involved, competent, aware, and possesses the necessary skills to operate and maintain the system.

Who needs training?

Internal auditors need specialized training to conduct effective audits. Next are health and safety managers who need comprehensive knowledge of the standard and implementation strategies. And finally, your employees, those who need awareness training on the policy and are at risk in their area.

Types of training:

- Awareness Training: Just the basic overview for all employees.

- Implementation Training: Focus on developing documentation and controls.

Lead Auditor Certification: Comprehensive training accredited by bodies like IRCA or CQI for those who will manage the audit program.

Maintaining and Improving Your OH&S System

Certification is just the beginning, as it is an ongoing commitment to improvement once acquired.

- Monitor and Measure Performance

Continuously track KPIs like incident rates, risk levels, and compliance status.

- Corrective Actions and Continual Improvement

Quickly address any anomalies and weaknesses in your system, and you can use your data from incidents, audits, and measurements.

- Prepare for Surveillance Audits

The certification body will conduct periodic audits to confirm your system is being maintained and is continually effective.

- Integrate Digital Tools

Use safety management software to make it easier to manage documentation, track incidents, schedule audits, and monitor overall safety performance.

Conclusion

Safety should never be just an option. And ISO 45001 is the framework that creates a safe and sustainable workplace.

By following the roadmap outlined in this guideline, you are helping your organization manage risks, stay compliant with regulations, reduce costs, and, most importantly, protect its most valuable asset: its people.

See Also: Understanding OHSAS 18001

Frequently Asked Questions

Q1: What are the ISO 45001 standards?

Answer: It’s a single standard that sets the requirements for an Occupational Health and Safety (OH&S) Management System. It aims to reduce workplace risks and promote safer working environments globally.

Q2: How to get ISO 45001 certified?

Answer: The process is a minimum of eight steps: Gap Analysis → System Development and Implementation → Employee Training → Internal Audit → Management Review → Selection of a Certification Body → Stage 1 and Stage 2 External Audits → Certification.

Q3: What is the main benefit of ISO 45001 certification?

Answer: The primary benefit is the reduction of work-related incidents, injuries, and ill health, which in turn leads to a healthier workforce, lower operational downtime, reduced costs, and improved regulatory compliance.

Q4: What is the difference between ISO 14001 and 45001?

Answer: ISO 45001 is the standard for Occupational Health and Safety (OH&S). Focuses on preventing injuries and ill health to workers and providing safe and healthy workplaces. Meanwhile, ISO 14001 is the standard for Environmental Management Systems (EMS) that focuses on the organization’s impact on the external environment, including pollution prevention, waste management, and resource utilization.